First, UV laser characteristics description

The ultraviolet laser wavelength is short, energy concentration, high resolution, especially has the characteristic of "cold processing", can directly destroy the connection material chemical bond, without producing to the peripheral heating, therefore becomes the ideal tool of processing fragile material, and can carry on the perforation, cutting, ablation to many kinds of materials, has the wide application in the field of micromachining.

1. Gas UV laser

Gas UV lasers are excimer lasers, argon ion lasers, nitrogen molecule lasers, fluorine molecule lasers, helium cadmium lasers and so on. The gas ultraviolet laser used for laser processing mainly has the excimer laser.

Excimer is a kind of excimer in the excited state composite into molecules, in the base state dissociation into atomic unstable connective matter. In excimer laser systems, the leap occurs from the bound excited to the repelled fundamental state, and is therefore a free leap of bound origin. Excimer laser is a kind of pulsed laser, the working medium is generally a certain proportion of mixed inert gas and strong electron halogen element gas, when the base state of the inert gas atom is excited, the extra-nuclear electron is excited to a higher orbit and thus change the electronic shell layer all filled state, so that it and other atoms to form an excimer, when the excited state of the molecule leaps back to the base state, immediately decomposed, reverted to the original properties! The laser emits high energy ultraviolet laser, which is amplified by the resonant cavity and releases photons at the same time.

2. Solid-state ultraviolet laser

The general produce ultraviolet excitation spectral line method has two kinds: one is directly using infrared all solid-state laser triplex frequency or quadruple frequency obtain 355nm or 266nm ultraviolet excitation spectral line, another kind of method is first use frequency doubling technology to get the second harmonic, then use and frequency technology to get ultraviolet excitation spectral line. The former method effective nonlinear coefficient is small, the conversion efficiency is low, the latter method because of the use of the second nonlinear polarization rate, the conversion efficiency is going to be higher than the former kind many. The solid ultraviolet laser relative to the excimer laser has the advantages of compact volume, easy maintenance, easy operation and so on.

3. Application advantages

There are three advantages of UV lasers in laser processing: first, the shorter wavelength of UV lasers can process very small parts; Two is the ultraviolet laser for laser processing directly destroy material chemical bond, is "cold" processing, has a small heat affected area; Three is most materials can effectively absorb ultraviolet light, can process many infrared and visible light laser processing can't material, and the ultraviolet laser especially solid-state UV lasers are becoming increasingly compact, high average power, easy to maintain, easy to operate, low cost and high productivity. Therefore, it has been widely used in laser processing fields such as bioengineering, material preparation, all-optical optical device production, integrated circuit board and semiconductor industry.

4. Industry Applications

Application area Legend Brief description

Chip processing

(Bioengineering) Laser excimer fabrication of polymer microfluidic chips for analysis, synthesis and cell culture, DNA sequencing, gene mutation and other applications.

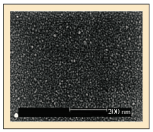

Material Preparation

Nano Si film

The method of using laser ablation technology to make its surface quickly heated and melted evaporate, and then cooled crystallization growth. Advantages: Firstly, the preparation cycle is short; secondly, the UV laser can be absorbed by many materials, such as ceramics, metals, polymers, etc.; Thirdly, it has a very small heat affected zone.

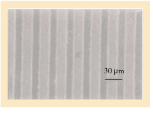

All-optics

Diffraction grating structure The traditional method is to use a diamond cutter to engrave, in the process of engraving tool wear is very serious, the special grade knife material diamond cutter can only engrave a few pieces of grating. Laser ablation is used to produce a grating stripe structure on the surface of the material, the thin film in the scanning area is ablated, the substrate is exposed, and a grating structure is formed on the surface of the material. Easy and fast operation

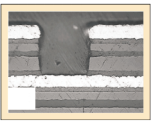

Integrated circuit board,

PI film drilling 100µm holes in the polymer and copper laminated circuit board, and cutting.

Semiconductor industry - Mainly used for crystal cutting, which is not easy to break and does not damage the surrounding devices.