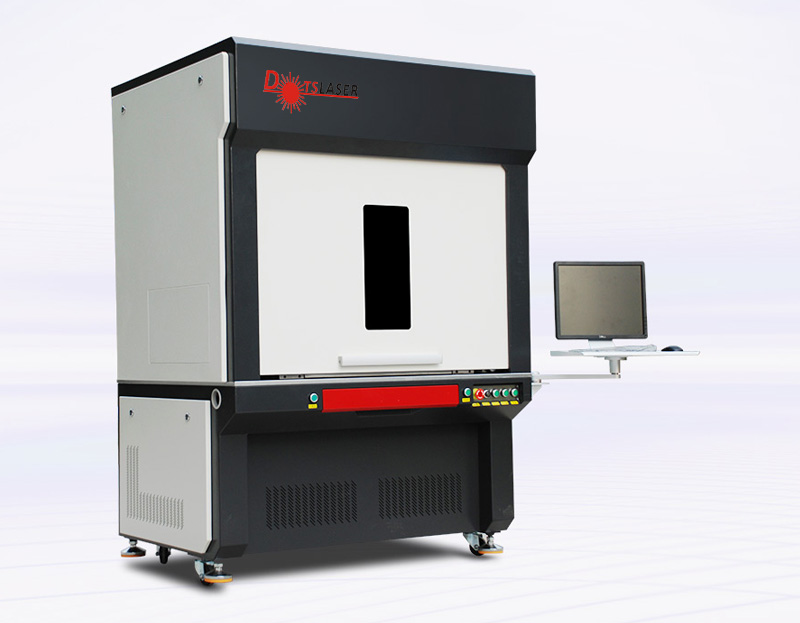

gold silver brass copper aluminum precision cutting system

gold silver brass copper aluminum precision cutting system is a processional and leading technology for high precision cutting on small parts, especially used for cutting precious material, such as gold, silver, aluminum,brass, which is high laser beam reflective material

gold silver brass copper aluminum precision cutting system video show

Product introduction

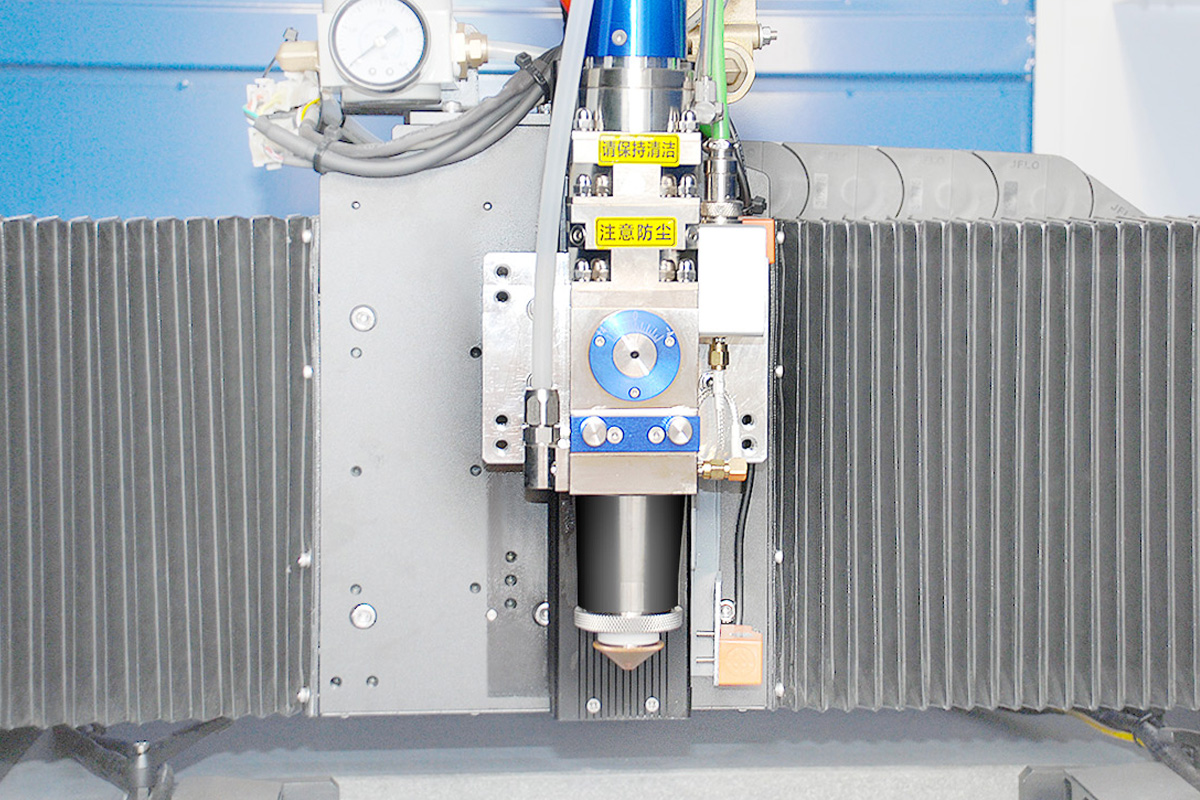

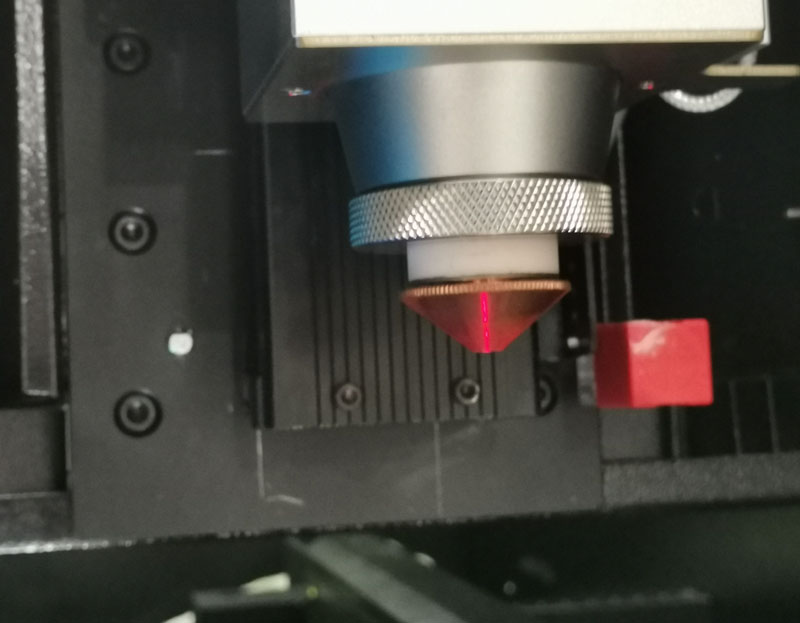

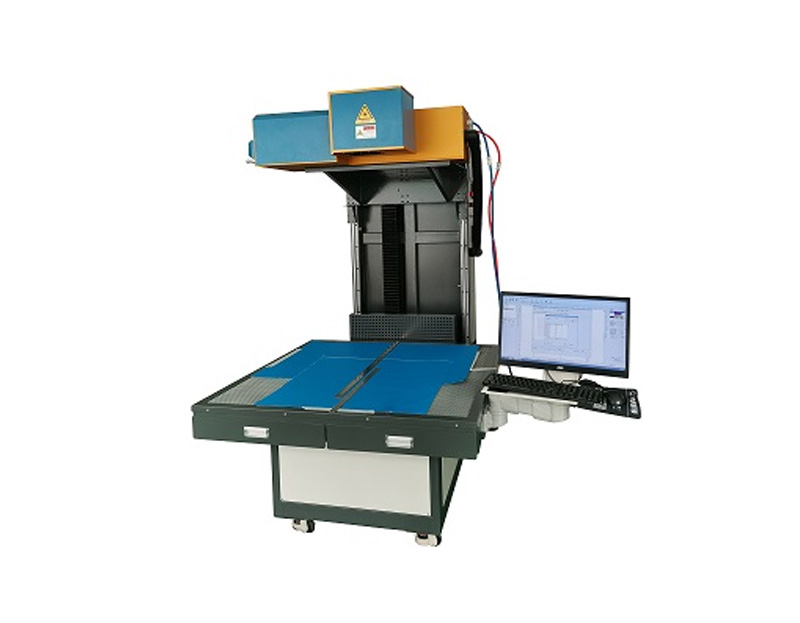

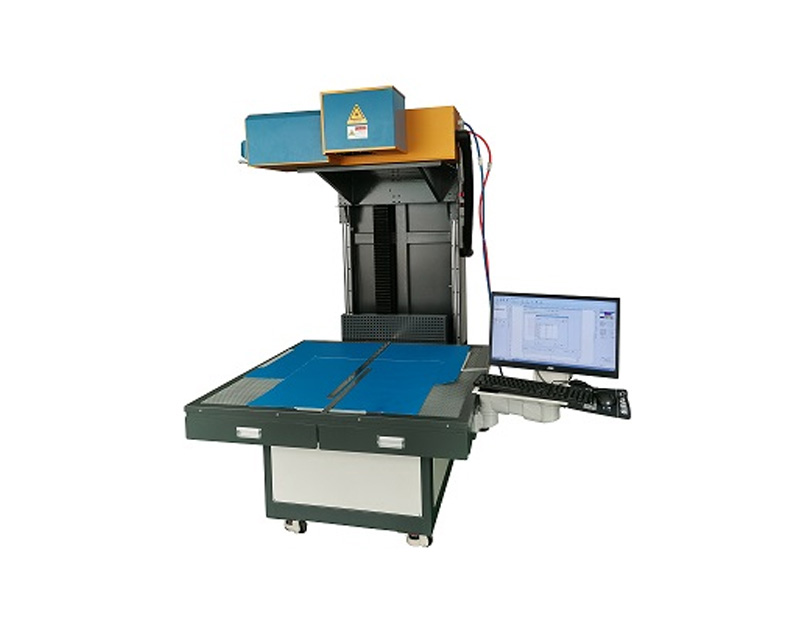

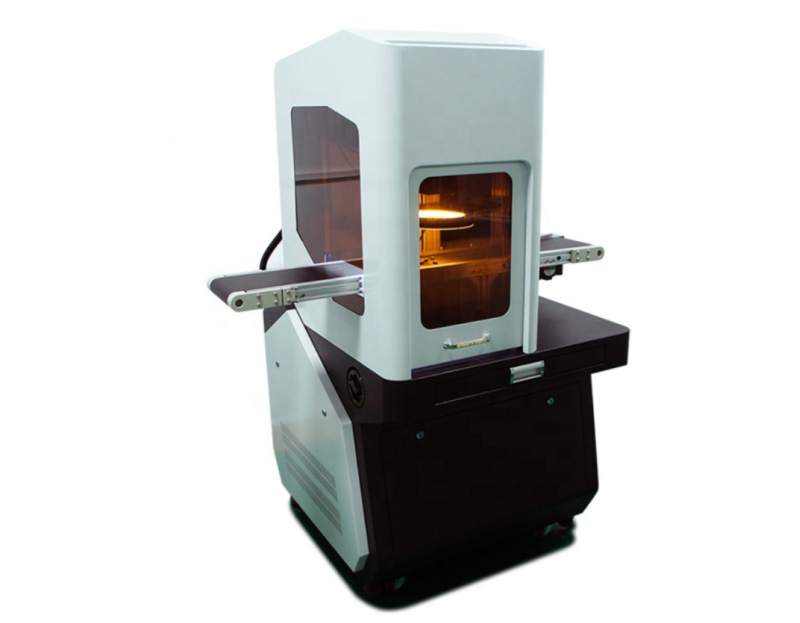

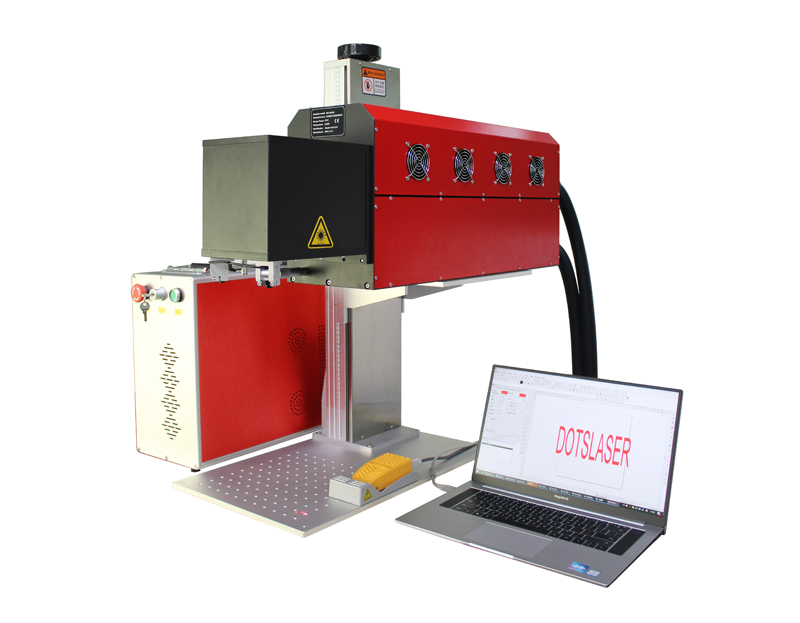

gold silver brass copper aluminum precision cutting system adopts laser original double-layer precious metal recovery system. Imported fiber laser, high-configuration cutting head, high-precision rotary servo motor, with professional laser cutting control software, supporting automatic follow-focus system, can automatically follow the workpiece bending and undulation to adjust the focus position during cutting to ensure precision cutting and quality. Optional automatic feeding cutting system and bracelet, ring rotary cutting system.

Model introduction:

1. The original recovery system - fully enclosed double-layer protection, cutting in the cavity, the recovery rate is over 99.95%.

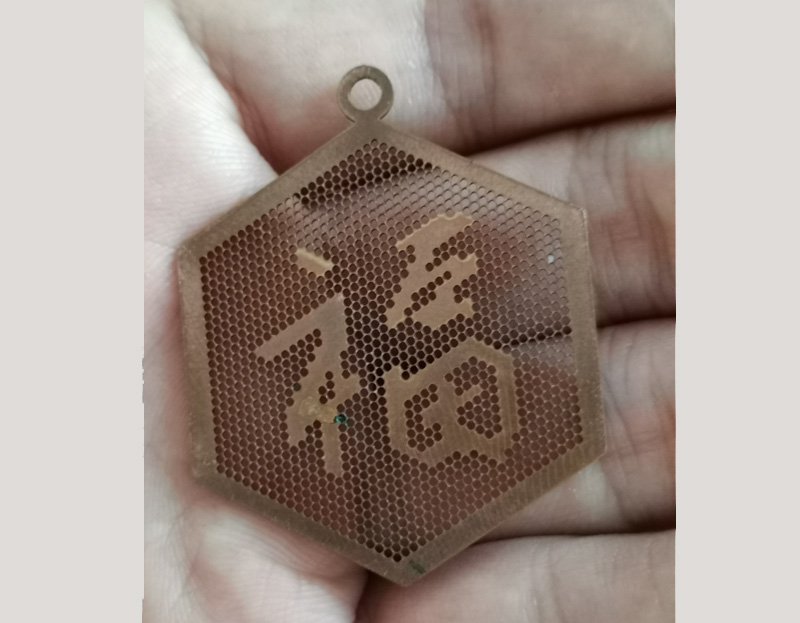

2. High cutting precision, fast speed, narrow slit, extremely small heat-affected zone, smooth cutting surface without burrs.

3. Fiber laser life up to 100,000 hours

Application range:

18K/24K gold, 925 silver, jewelry metal, precision accessories.

What is the difference between high precision laser cutting machine and traditional cutting method?

Compared with traditional cutting methods, the advantages of laser cutting mainly include fast cutting speed and high processing accuracy. Specifically include:

1. High precision, high speed, narrow slit, small heat affected zone, smooth cutting surface;

2. The processing flexibility is good, and it can also cut pipes and other special-shaped materials;

3. Non-deformation cutting can be performed on materials of any hardness;

Fast laser cutting speed: The cutting speed of laser cutting is more than 10 times that of the traditional cutting method, and the quality of laser cutting is high: the traditional cutting method has a large loss of materials, and at the same time, from the perspective of cutting effect, it is not as good as laser cutting. Secondary processing is required, and the accuracy is relatively lacking. The reason why laser cutting has very little damage to materials is that it is a non-contact processing technology, no secondary processing is required, and the accuracy is better than traditional cutting methods.

GUANGZHOU DOTSLASER is a professional laser equipment manufacturing company. The company researches, develops, manufactures and sells laser series products, including small-format laser marking machines, large-format laser marking machines, laser hand-held welding machines, laser automatic welding machines, and YAG lasers. Dozens of industrial laser equipment such as marking machines, CO2 laser marking machines, and laser cutting machines. Excellent product quality and perfect after-sales service, return new and old customers to our dependence and support.