Laser marking technology is one of the largest applications of laser processing. With the rapid development of the second industry, the application of lasers in various processing and manufacturing industries is becoming more and more widespread, such as laser marking, laser cutting, laser welding, laser drilling, laser proofing, laser measuring, laser engraving, etc., which accelerates the rapid development of the laser industry while accelerating the production of enterprises.

The UV laser has a wavelength of 355nm, which has the advantages of short wavelength, short pulses, excellent beam quality, high precision, and peak power; therefore, it has a natural advantage in laser marking. Unlike infrared lasers (wavelength 1.06μm), it is not the most widely used laser source for material processing. However, plastics and special polymers such as polyimides, which are used in large quantities as base materials for flexible circuit boards, cannot be finely processed by infrared or "thermal" treatment.

Therefore the ultraviolet laser and green light, infrared compared, has more small thermal effect, with the laser wavelength becomes shorter, all kinds of materials have higher absorption rate, even directly change the molecular chain structure, in the micro, nano level ultra-fine processing for thermal effect is very sensitive to the material, ultraviolet laser has more obvious advantages.

DOTSLASER uv water-cooled laser, at 30Khz repetition frequency can provide an average output power of 1-5W 355nm ultraviolet laser, laser spot small, narrow pulse width, can carry out the processing of fine parts, even at a low pulse energy level, can also get a high energy density, effective material processing, therefore, can get more accurate marking results.

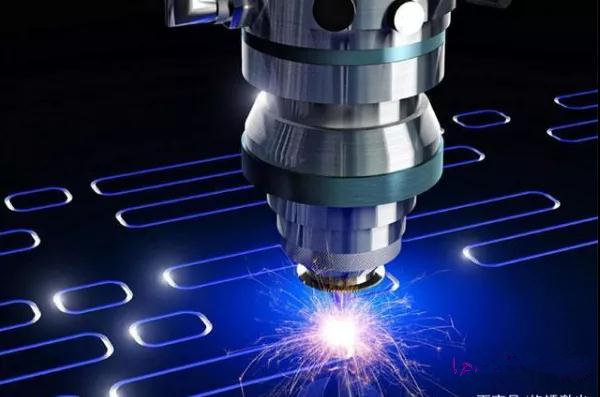

Laser marking works by using a high energy density laser to irradiate the workpiece locally, causing the surface material to vaporize or a photochemical reaction that changes color, thus leaving a permanent mark. Like keyboard keys, for example! Now many keyboards on the market are using inkjet technology, it seems that the characters of each key is clear, beautiful design, but after a few months, it is estimated that we will find that the characters on the keyboard began to become fuzzy, more familiar with the computer friends, it is estimated that by feel also operate, but for most people, the key fuzzy estimates will be a handful.

DOTSLASER 355nm UV laser belongs to the "cold light" processing, water-cooled UV laser head and power box can be separated, the laser head is compact and easy to integrate, and at the same time, laser air-cooled heat dissipation aluminum profiles integrated into the laser head, good heat dissipation energy. Marking on the plastic material, with advanced non-contact processing, does not produce mechanical extrusion or mechanical stress, so it will not damage the processed goods, and will not produce deformation, yellowing, charring and other phenomena; thus, it can complete some conventional methods can not be achieved by modern technology.

With remote computer control, it has excellent application characteristics in the field of special material processing, which can significantly reduce the thermal effect on various material surfaces and greatly improve processing accuracy. UV laser marking can hit a variety of characters, symbols and patterns, etc., the size of the characters can be from millimeters to the micron scale, which also has a special significance to the product anti-counterfeiting.

Accelerating the development of the electronic industry at the same time, industry, OEM technology is also constantly innovating, traditional processing methods have been unable to meet the growing market demand, UV laser precision laser has a small spot, narrow pulse width, thermal impact, high efficiency, environmental protection, precision machining without mechanical stress and other advantages, is the ideal improvement of the traditional process.