Carbon Steel Fiber Laser Metal Sheet Cutting Machine

High performance fiber transmission can make sure the same quality cutting effect in every point of the material

1. High performance fiber transmission can make sure the same quality cutting effect in every point of the material

2. High efficiency,fast cutting speed,photoelectric conversion rate about 35%

3. Low gas consumption,it has the cutting technology specially for steel board and produce no gas when cutting

4. Low power consumption .environment -friendly and energy -saving,reduce 20%-30% power compared with co2 cutting machine

5. Maintenance-free ,fiber transmission without reflection lens,can save time in light path adjustment fiber exerts its features better in thin metal sheet cutting

6. We designed to satisfy the customer who want lower investment while higher stability laser machines. We chose to use import laser generator, gantry bed structure which ensure the machine stability,fast cutting and long life span.

Advantage of laser cutting machine

1) Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2) High cutting speed: Cutting speed is more than 60m/min

3) Stable running: Adopting the top world import fiber lasers, stable performance, key parts can

reach 100,000 hours;

4) High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine,

fiber laser cutting machine has three times photoelectric conversion efficiency

5) Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate

is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser

cutting machine. Fiber line transmission no need reflect lens, save maintenance cost;

6) Easy operations: fiber line transmission, no adjustment of optical path;

7) Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

Parameters

| Model | DS-3015 | DS-4015 | DS-6015 |

| Laser power | 700W-3000W | 1000W-3000W | 1000W-3000W |

| Laser wave | 1070nm | 1070nm | 1070nm |

| Working area | 3000mm*1500mm | 4000mm*1500mm | 6000mm*1500mm |

| X/Y-axis positioning accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

| X/Y-axis re-positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y-axis max travel speed | 120m/min | 120m/min | 120m/min |

| Cooling Mode | Water Cooling | Water Cooling | Water Cooling |

| Power request | 380v 50hz 3ph | 380v 50hz 3ph | 380v 50hz 3ph |

| X,Y axle Max. accelerate speed | 1.2G | 1.2G | 1.2G |

| Working temperature | 0-45℃ | 0-45℃ | 0-45℃ |

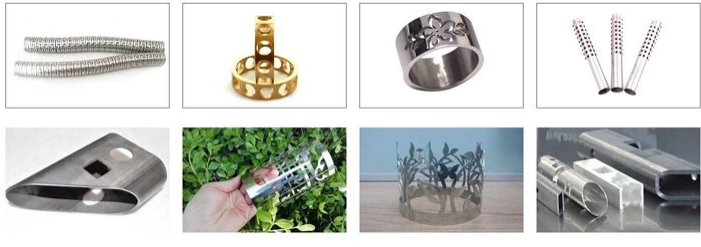

Application

1. Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

2. Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Pre-sale service

1. Free sample cutting,

For free sample cutting/testing, please send us your CAD file, we will do cutting here and make video to show you the cutting ,or send sample to you check cutting quality.

2. Customized machine design

According to customer’s application, we may revise our machine accordingly for customer’s convenience and high production efficiency.

Service after sales

A. Machine will be supplied with training video and user's manual in English for installation, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone, skype….

B. We offer technician to customer's site for installation and training, customer shall cover visa, ticket, local living cost.

C. Customer may come to our factory for training. We will offer training of installation, operation, machine trouble-shooting, and maintenance.

During training in our workshop, we offer free training and living cost for 7 days, limit 2 people.

Warranty

a).1Year for the whole machine(Man-made Damage is negotiated.).

b).Laser source 2 Years warranty

c).Lifelong maintenance and spare parts supply

d).Free training for operation staffs. (engineer can go abroad is negotiated.)

Sample

FAQ

Q1.Which kind of machine is more suit for me?

It is according the material and processing thickness and working area.24 hours free online consulting service, we will analysis for customer's needs, provide right laser cutting machine for customers.

Q2. How to support me if I don't know how to use it?

There are English manual and guide video. We also can dispatch our engineers to customer's company to provide training and support and free training in our factory.

Q3. If machine have any problem after I ordered it, how could I do?

Free parts send to you in machine warranty period if machine have any problem. Please feel free contact us if your machine have any problem. We will give you 24-hour online and telephone service.